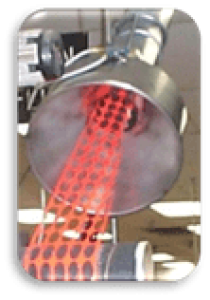

Patented Energy Saving Adjustable Inducer/Venturi (*PATENT No 6732897)

Where a continuous stream of waste material is beneficial, the AirTrim Patented* Energy Savings Venturi can reduce energy costs up to 30%.

The Patented adjustable feature allows fine tuning the air flow for the most efficient pneumatic handling of continuous waste. This product is available in mild or stainless steel. Available for new systems or retrofits, with intake diameters from 3” for narrow trims up to 32” for larger objects as such as in Recycling Facilities or Mill applications.

Trim Cutters

AirTrim’s standard In-line Trim Cutters efficiently handle most any trim or matrix application, processing the waste into the proper size for pneumatic conveying to the desired location and/or receptacle. Helps reduce trim waste volume in paper, plastic, and foil converting operations.

Air/Material Separators

Separators are used extensively in the paper, film, foil and converting industries to separate conveyed waste material from conveyance air flow. The same separator designs are increasingly used as Pre-Separators to improve a wide variety of dust handling systems.

Round Duct Inline and Capped Silencers

For both air and mechanical sounds. Major factor in reducing system noise levels to meet OSHA standards. Silencers have a major effect on reducing sounds related to cutter/chopper systems, along with other machine related functions.

Round Duct Static Eliminators

A static eliminator produces an energy field that neutralizes the static charge and allows the material to flow freely through the conveying lines.

Grounding wires will direct a static charge safely away from the outside of a duct line but have little impact on the continual build up of static on the inside of the duct. Coating the inside of the duct with a non-stick polymer may reduce the amount of friction but does not eliminate it. Over time the coating may wear off exposing the line to static “cling” once more.

Matrix Twister

Features:

● Increase Label Production – run press continuously

● Improve Label Quality -concentrate on production

The Matrix Removal System*, featuring the Matrix Twister™ is a comprehensive system designed specifically to pneumatically convey PSA (pressure sensitive adhesive) waste matrix and edge trim from a label press or die cutter to a compactor, baler, or dumpster. The patented* design“twists” the matrix into a roped form for ease of conveying, reducing the amount of exposed adhesive by collapsing it onto itself. The more aggressive the adhesive, the better it sticks to itself and the easier it is to convey. A fine, food-grade silicone mist, introduced into the inlet of the system, ensures system performance.

To see the matrix removal operation from a press like yours click on this link.

*PATENT NO 6,547,913 B1

Mister Systems to Improve PSA Matrix Conveyance

The Silicone Mister System allows plants to alleviate the problems associated with efficiently transporting PSA materials in pneumatic conveying systems; whether it is delaminated trim or label matrix.

The system automatically meters out the exact quantity of needed silicone, at the optimum pressure, on a timed basis.

Extensive research has determined that pure food grade silicone best neutralizes the adhesive nature of PSA in conveying applications. It has “0” flammability, “0” reactivity, and a “0” health score on the HMIS rating scale, making it exceptionally safe to use. It is not subject to break down in extreme heat like oil systems and it does not leave a sticky residue in the duct like soapy water systems.

Silicone

Silicone used in conjunction with a Mister System allows plants to alleviate the challenges associated with efficiently transporting PSA materials in pneumatic conveying systems.

Pure food grade silicone best neutralizes adhesive nature of PSA in conveying applications. Plus, it has “0” flammability, “0” reactivity, and a “0” health score on the HMIS rating scale, making it safer to use. It is not subject to break down in extreme heat like oil systems and it does not leave a sticky residue in the duct like soapy water.

Staticide

Applied with silicone mister system, STATICIDE® eliminates static electricity in pneumatic conveying applications.

This solution inhibits charge generation, providing dependable protection by allowing static to dissipate. Made of a proprietary blend of electro-active polymers which allows the coating to be inherently dissipative regardless of ambient relative humidity.

Duct – Quick Fit

This Quick-Fitting, Clamp Together duct provides design flexibility, simplicity of installation, the ability to reconfigure the layout if necessary, and the ease of adding additional components.